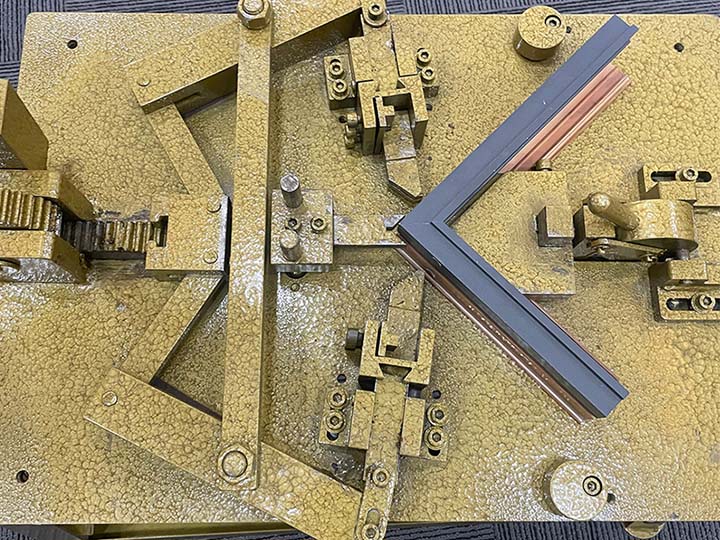

Aluminium crimping tool for window, door profiles

Aluminium crimping tool is a very easy-to-use equipment. Simple installation, convenient use and low price are its outstanding features.

Aluminium crimping tool is a very easy-to-use equipment. Simple installation, convenient use and low price are its outstanding features.

Aluminium crimping tool is a very easy-to-use equipment. Simple installation, convenient use and low price are its outstanding features. Our door and window aluminum profile corner forming machines are of high quality and have been welcomed by many customers.

Aluminium crimping tool is specially designed for extruding aluminum profiles for door and window frames. By extruding, the aluminum profile and the corner code are snapped together to form the aluminum profile frames for doors and windows with 90-degree angles. The use of this door and window aluminum profile angle forming machine helps customers can form their own aluminum profile frame and save cost. Aluminum profile for doors and windows is one of the more common aluminum profiles, which is widely used in daily life. We can manufacture aluminum profiles of various materials and have rich experience in customization, so feel free to come and consult us!

| Name | aluminium crimping tool |

| Warranty of core components | 1 year |

| Core components | gear, bearing |

| Weight | 50kg |

| Function | aluminum profile corner combining |

| MOQ | 1 set |

| Lead time (days) | 7 to be negotiated |

| Usage | aluminum materials |

1. Flexible application. Users can assemble any length and door and window frame aluminum profiles according to their needs. The time and place of application depends on the demand.

2. Good quality and low price. As the angle forming machine is manual, it is advantageous in terms of price. Help customers save the cost of making door and window frames.

3. Simple operation. The use of the machine is very simple, only need to read the manual to operate. There is no need for professional learning.

4. Long service life. The aluminum profile corner forming machine for doors and windows we made is made of high quality materials. Generally there is no problem, and the number of repairs is small.

Aluminium crimping tool can deal with aluminum profile frames for doors and windows that need angle yards to be connected. At the same time the frame is a common aluminum profile for doors and windows used in houses. Do not use aluminum profiles that are too hard and do not belong to the aluminum profiles for doors and windows.

Since it is a aluminum window corner crimping machine, it is usually suitable for the following usage scenarios:

1. The quantity to be assembled is relatively small. Because it is a manual cornering machine, the manual operation efficiency is not as high as the mechanical efficiency. Therefore, a small amount of aluminum profile frame assembly is and suitable for the use of this equipment.

2. Small budget. Customers with small budget can consider using this equipment. Our doors and windows aluminum profile angle forming machine is good quality and low price.

3. Small scale door and window angle forming machine business. If you want to start a small-scale door and window cornering business, you can choose to use this equipment.

4. For special projects: manual window and door cornering machines can be used to handle special projects such as window and door frame repair or very customized windows and doors. They provide more manual intervention to meet special requirements.

1. One year after-sales service. You can contact us if you encounter any problem within one year of receiving the corner forming machine. We can help you solve the problem.

2. Online Q&A. Customers receive the equipment have any questions about installation, use, can be solved by voice or video.

3. Instruction manual. Each door and window corner forming machine will have English instructions to help you assemble and use.

Name: Aluminum Powder Coating Roller Blinds Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Zebra Blinds Bottom Rail Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminium Curtain Track Zebra Blinds Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Blind Roller Tube Aluminium Pipe Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Extruded Curtain Bottom Rail Section

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Office Partition Aluminum Extrusion

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8