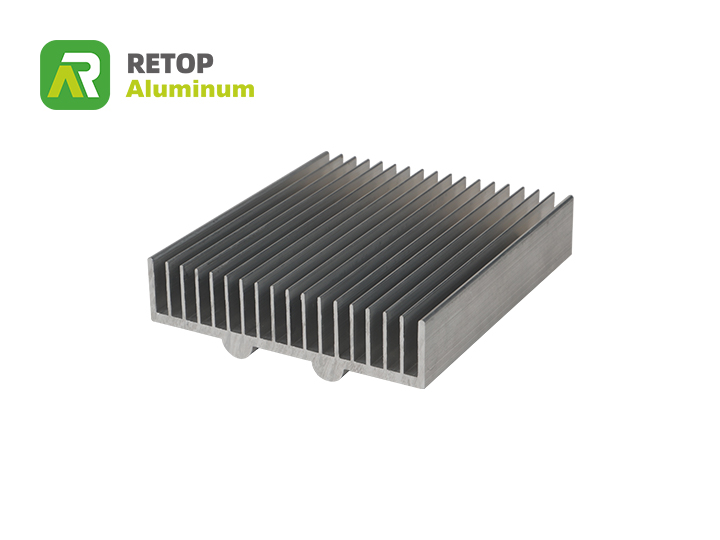

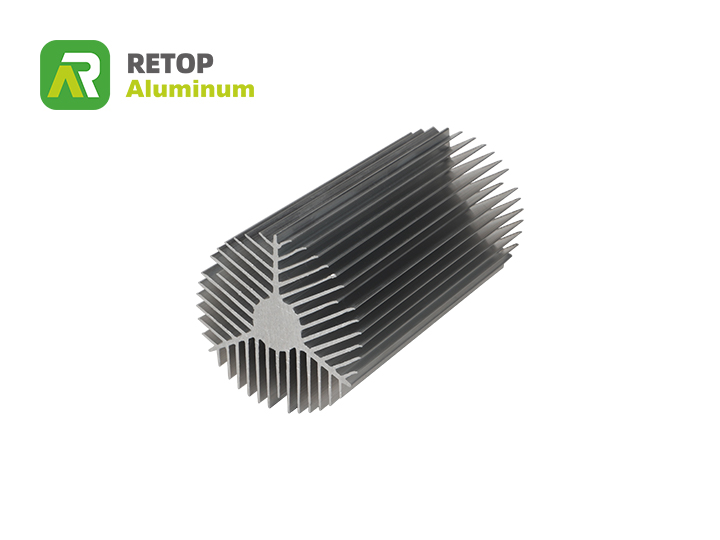

Aluminium extrusion heat sink profile

Aluminium extrusion heat sink profile is radiator specially designed and manufactured using aluminum profiles.

Aluminium extrusion heat sink profile is radiator specially designed and manufactured using aluminum profiles.

Aluminium extrusion heat sink profile is radiator specially designed and manufactured using aluminum profiles. A radiator is a device used to dissipate heat or reduce temperature. Commonly used in electronic equipment, computers, automotive engines, industrial machinery, and other applications that require cooling. Because aluminum profiles have good thermal conductivity, corrosion resistance and light weight, they are widely used in radiator manufacturing.

Aluminium extrusion heat sink profile is a collective name for a series of aluminum profile devices used to conduct and release heat. Aluminum profile heat sinks have the characteristics of beautiful appearance, light weight, good heat dissipation performance, and good energy saving effect. Heat sink aluminum profiles usually have special cross-sectional designs to increase surface area and thereby improve heat dissipation efficiency. They can also be machined and customized to fit different types and sizes of heat sinks.

With the rapid development of industrial mechanization, the development of aluminium heat sink extrusions is getting faster and faster. Radiators are used in every aspect of our lives. For example: electrical appliance radiators, electronic radiators, power supply radiators, LED light heat sinks, automobile radiators, communication base heat sinks, locomotive radiators, wind radiators, mechanical equipment radiators, new energy heat sinks, power semiconductor radiators , inverter radiator, CPU, graphics card, motherboard chipset, hard drive, chassis, power supply, etc. in the computer will all need radiators.

Application fields: machinery, automobiles, wind power generation, engineering machinery, air compressors, railway locomotives, household appliances and other industries.

The most common heat sinks are 6061 and 6063 aluminum profiles. They are in the 6000 series aluminum alloys which have good thermal conductivity, are versatile and easy to machine.

Extruded heat sinks are the most commonly used heat sinks for thermal management today. They are manufactured by pushing a hot aluminum billet into a steel mold to create the final shape. The most common aluminum alloy is 6063-T5, but other 6000 alloys can be checked as needed. When the material is extruded, the initial rod is 30-40 feet long and very soft. Stretch the material by grabbing the ends to create a straight rod. After stretching, the material can be air-aged or over-aged, depending on the desired final hardness of the material. After the aging process, the material is cut to final length and ready for any final processing.

| Material | aluminum alloy 6063 |

| Length | 5.8-6.0m,customized size |

| Temper | T5, T6 |

| Surface treatment anodizing | silver, champagne, bronze, black, gold, imitating steel, titanium |

| Deep processing ability | drilling, bending, cutting, etc |

| Packing protective tape | shrink film, plastic wrap or accroding to client requirement |

We can provide different surface treatments. The most common surface treatment for heat sinks is anodizing. This electrochemical process improves surface emissivity, corrosion resistance, wear resistance and electrical isolation. However, it is not recommended to use coatings such as paint or powder as they act as insulators. Radiators can be anodized using colored dyes on our extrusion equipment. We customize surface treatments to meet our customers’ specific needs.

One way to help maximize the surface area of an extruded heat sink is to cross-mill after extrusion. CNC machining is a very precise method of converting the fins on the extruded heat sink into pins. The pins help maximize heat dissipation, making your heat sink more efficient. In addition, we can also perform other secondary processing, such as drilling, stamping, and cutting. If you have any secondary processing needs please contact us.

Name: Aluminum Powder Coating Roller Blinds Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Zebra Blinds Bottom Rail Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminium Curtain Track Zebra Blinds Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Blind Roller Tube Aluminium Pipe Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Extruded Curtain Bottom Rail Section

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Office Partition Aluminum Extrusion

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8