Aluminium Profiles

Grade:6000 series

Temper:T5,T6

Surface Treament:Powder Coating, Anodized, Mill Finish, etc

Certification:ISO9001, ISO14001

Grade:6000 series

Temper:T5,T6

Surface Treament:Powder Coating, Anodized, Mill Finish, etc

Certification:ISO9001, ISO14001

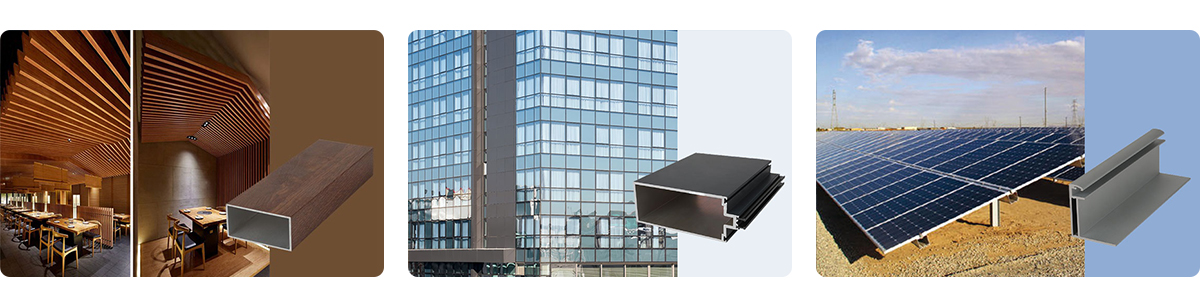

Aluminum profiles are extruded aluminum products that are widely used in different industries. These profiles can be customized to meet specific design requirements, making them suitable for a variety of applications. One of the main advantages of aluminum extrusions is their lightweight design. Aluminum is a lightweight material that is easy to transport and install, while also reducing the overall weight of the structure, increasing efficiency and performance. In addition, the aluminum profile has a high strength-to-weight ratio, making it strong and durable despite its lightweight design. Another advantage of using aluminum profiles is their versatility. Aluminum profiles can be extruded into a variety of shapes and sizes, and can be easily customized to meet specific design requirements. This makes them suitable for a wide variety of applications, including automotive, construction, industrial and consumer products. Aluminum extrusions also have excellent corrosion resistance, making them suitable for outdoor applications as well as environments with high humidity or exposure to chemicals. They are also weather resistant, ensuring long-lasting performance and minimal maintenance requirements. Finally, aluminum extrusions are a sustainable and environmentally friendly choice. Aluminum is a highly recyclable material that can be reused numerous times without losing its properties, making it the material of choice for many industries. In addition, the lightweight design of aluminum profiles helps to reduce energy consumption and reduce the carbon footprint of structures and products. Overall, aluminum profiles offer a versatile, durable and sustainable solution for a wide range of applications in different industries. Their lightweight design, customization options, and outstanding performance make them a popular choice for a wide variety of applications, providing robust and effective solutions to meet the specific needs of different projects.

Aluminum profiles, also called aluminum extrusions, have a wide range of applications due to their versatility and flexibility. The following are some applications of aluminum profiles: Building and Construction: Aluminum profiles are widely used in the construction industry, such as door and window frames, curtain walls, roofing and cladding. These profiles have an excellent strength-to-weight ratio, corrosion resistance and durability, making them ideal for building and construction projects. Automotive: Aluminum extrusions are used extensively in the automotive industry for applications such as body structures, engine components, suspension systems and wheels. These sections offer lightweight and durable options that enhance vehicle performance, efficiency and safety. Electrical and Electronics: Aluminum extrusions are used in the construction of electrical housings, heat sinks and electronic components such as LED strips and circuit boards. These sections have excellent thermal conductivity and electrical insulation to help dissipate heat and protect electronic components. Furniture: Aluminum profiles are used in the manufacture of furniture such as tables, chairs and shelves. These parts offer lightweight and durable options for easy assembly and customization. Industrial Applications: Aluminum extrusions are used in various industrial applications such as conveyor systems, machine frames and safety barriers. These sections are high strength and durable for heavy duty use in harsh environments. Overall, aluminum profiles offer a versatile and cost-effective solution for a variety of applications. Their lightweight and durable nature makes them ideal for industries and applications requiring strength, flexibility and design versatility.

1. Strong plasticity

2. Good sealing performance

3. Long service life

4. Environmental protection and energy saving

5. Excellent weather resistance

6. Elegant decoration effect

ODM & OEM Offered

We own 18 Extruding Lines from 500UST to 4000UST Extruder, 2 Horizontal and 1 Vertical Powder Coating Lines, 2 Anodizing Oxidation Lines, Deep-processing Workshop and CNC High-precision Processing Workshop to meet all the customer’s demands for the aluminum products in different levels of alloy, finishes and tooling process. With our strong r&d capabilities, we can provide a one-stop service from custom design, manufacturing, packaging, inspection, logistics to OED/ODM integrated solutions to meet your specific needs.

Q1:Are you a factory or trading company?

A1:we’re a self -own factory, with export license.

Q2:Location? How can I visit there?

A2:*Our factory locates in Zhengzhou, Henan, China.

*The nearest airport is Xinzheng airport.

Q3:Lead time for new molds &mass production?

A3:*7-10 days to build the new moulds.

*Mass production takes 20-25days for a 20gp,25-30days for a 40hq.

Q4:What certification do you have?

A4:we are certificated by ISO 9001:2008, factory is reliable and quality is guaranteed.

Q5:Payment terms?

A5:Telegraphic Transfer (T/T) and Letter of Credit (L/C).

Q6:Can you send me samples?

A6: Yes, Free samples, with freight is on your side.

Name: Aluminum Powder Coating Roller Blinds Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Zebra Blinds Bottom Rail Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminium Curtain Track Zebra Blinds Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Blind Roller Tube Aluminium Pipe Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Extruded Curtain Bottom Rail Section

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Office Partition Aluminum Extrusion

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8