Why use 6063 aluminium alloy profile to make heat sink?

6063 aluminium alloy profile is the most commonly used material. Most of the heat sinks in the market nowadays are made with 6063 aluminum alloy.Why is 6063 aluminum alloy the preferred material for making aluminium radiators? Here are the main reasons:

Advantages and disadvantages of 6063 aluminium alloy profile

6063 aluminum alloy profile has good corrosion resistance, good formability, weldability, and cutability.

Disadvantages of 6063 aluminum alloy material: hardness, strength in general. But does not affect the use.

The hardness and strength mentioned here are compared to the hardness and strength of iron, so the 6063 material is stronger than iron. Some industries require high strength of alloy, corrosion resistance or good welding performance. For example, solar energy frame, aluminum alloy tray and so on.

Advantages of using 6063 aluminum alloy profile to produce heat sinks

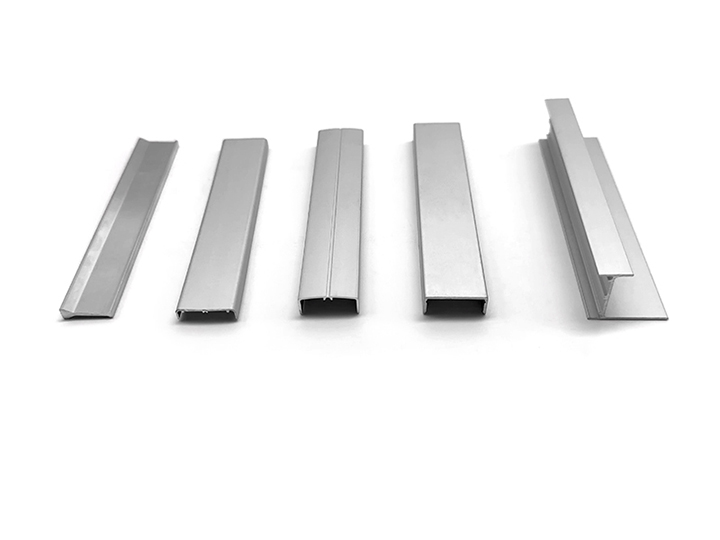

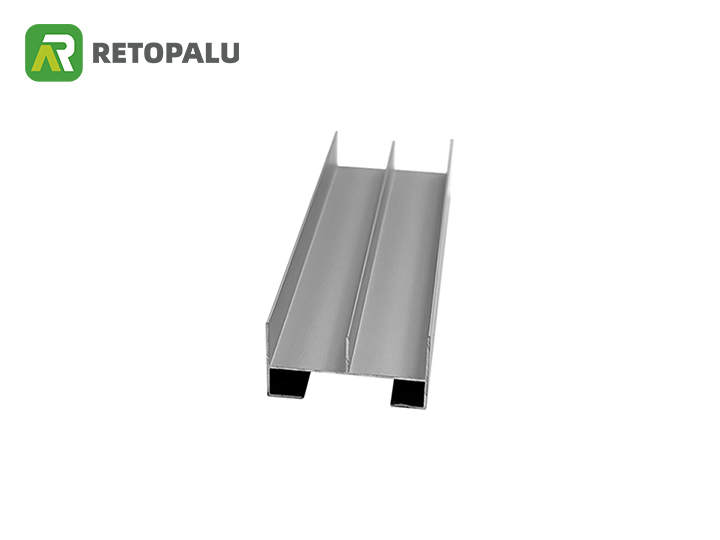

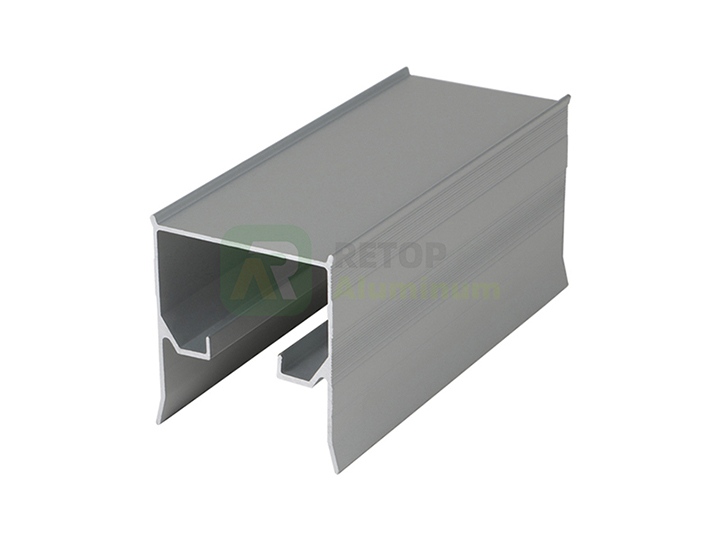

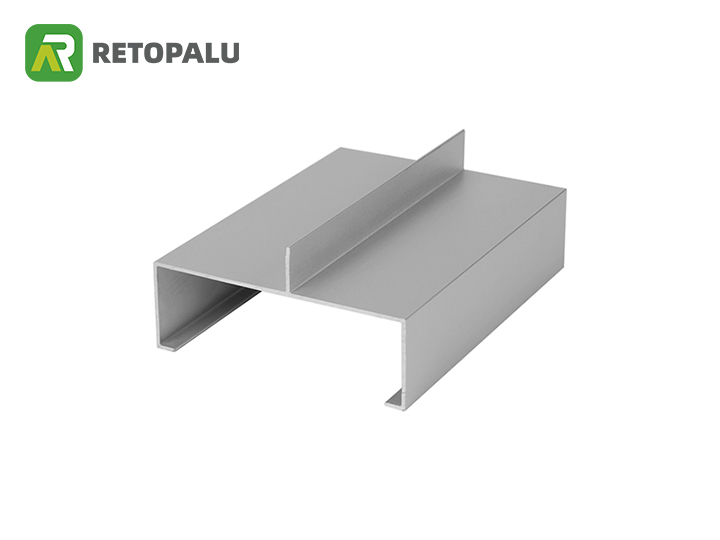

- 6063 aluminum heat sinks are available in a variety of shapes. And they have a number of features such as beautiful appearance, light weight and excellent heat dissipation performance. These aluminum profile radiators are precision machined and their surfaces are oxidized to improve the corrosion and wear resistance of the aluminum as well as its aesthetic appearance.

- 6063 aluminum profile electronic heat sinks have excellent thermal conductivity and can effectively help electronic products dissipate heat. Usually, the materials of aluminum profile heat sink include copper and aluminum alloy. And each of them has its advantages and disadvantages. Copper has excellent thermal conductivity, but it is more expensive, more difficult to process, heavier, has a smaller heat capacity, and is easy to oxidize.

- Pure aluminum is flimsy and usually requires the use of an aluminum alloy to provide sufficient stiffness. Aluminum alloy profiles have the advantage of being less expensive and lighter.

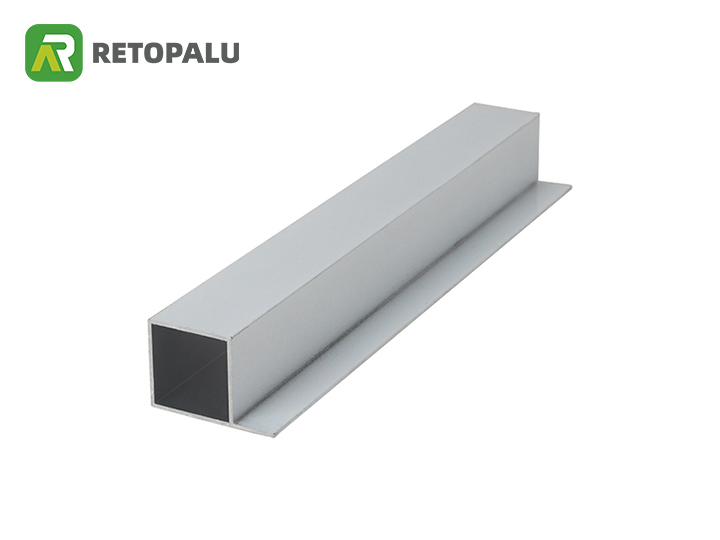

- 6063 aluminum profile radiator has a low density and is easy to process into various other parts. Due to the low density of aluminum alloy and diverse processing capabilities, the profile’s radiator cross-section can be designed to be wide and regular, so that product assembly and surface treatment can be completed at once.

- With excellent plasticity, 6063 aluminum profile radiators are able to accept a variety of surface treatments, offer a wide range of color options, and do not require welded joints, making them decorative, beautiful, and durable to meet the needs of personalized customization.