Great solar panel aluminum extrusion applications

Solar panel aluminum extrusion is specifically designed to support solar panels. Most areas choose aluminum alloys to support the solar panels. Solar panels are always exposed to the outside and can be affected by all kinds of weather. The corrosion-resistant nature of aluminum profiles is very much in line with the need to support solar panels. As a result, using solar bracket aluminum profiles saves money by reducing the number of times you have to replace aluminum profiles.

Why use solar panel aluminum extrusion?

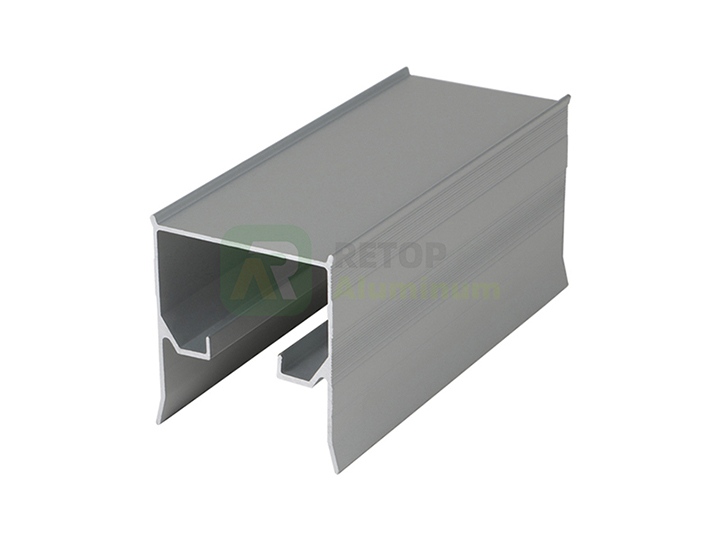

Solar panel aluminum extrusion can be extruded into various sizes. Therefore, they can be well installed around solar panels of various sizes. Besides fixing and supporting the solar energy, aluminum extrusion profile for solar panels can also protect the solar cells and other components. Nowadays, solar panel aluminum profiles are used by a wide range of customers for the following specific reasons:

1. Lightweight. Aluminum is the lighter weight of metals. This feature reduces the difficulty of transporting solar aluminum profiles. It saves people’s effort in installing and carrying aluminum profiles. This will also speed up the installation of workers. Therefore it is ideal for solar panels.

2. Strong corrosion resistance. Another remarkable feature of aluminum profiles is that they are very resistant to corrosion. Its service life can reach more than ten years. This is very suitable for solar energy use environment. Because solar panels are required to be installed outdoors, and will always be exposed to the sun. After a long period of exposure to the sun, rain and wind, it needs to be supported by extremely corrosion-resistant materials. Therefore, solar panel aluminum profile is very suitable for solar panels that need to be exposed to the external environment for a long time.

3. Thermal conductivity. Thermal conductivity is also one of the reasons why most people choose to use aluminum profiles. For example, aluminum extrusion heat sink profiles take advantage of this property of aluminum profiles. Aluminum profiles can conduct heat well and disperse it. Solar panels generate heat during operation, which needs to be dissipated in time. Therefore, the use of solar panel aluminum extrusion can avoid damage to the performance and efficiency of the panel.

4. Easy processing. Retop can produce solar aluminum profiles of various structures and sizes. It can also provide other deep processing of aluminum profiles. For example, cutting, bending, joining, drilling and other processing operations. It can also be customized according to your needs. It is the ductility of aluminum profiles that offers the possibility for a wide variety of structures and appearances.

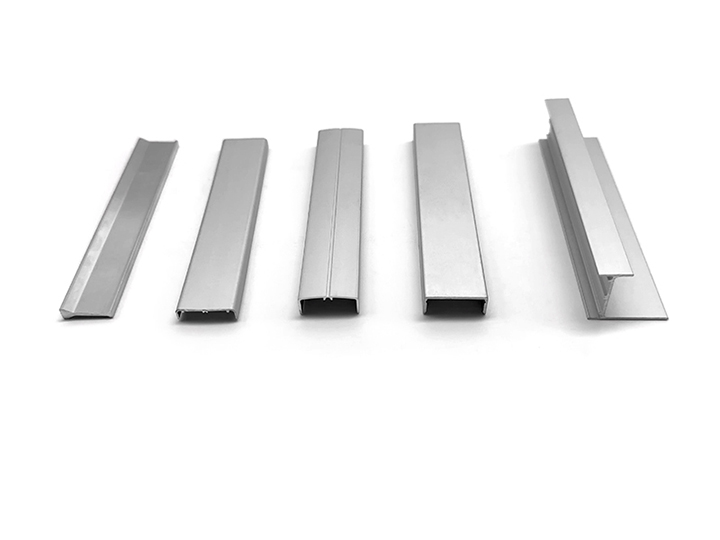

Solar panel aluminum profile spare parts

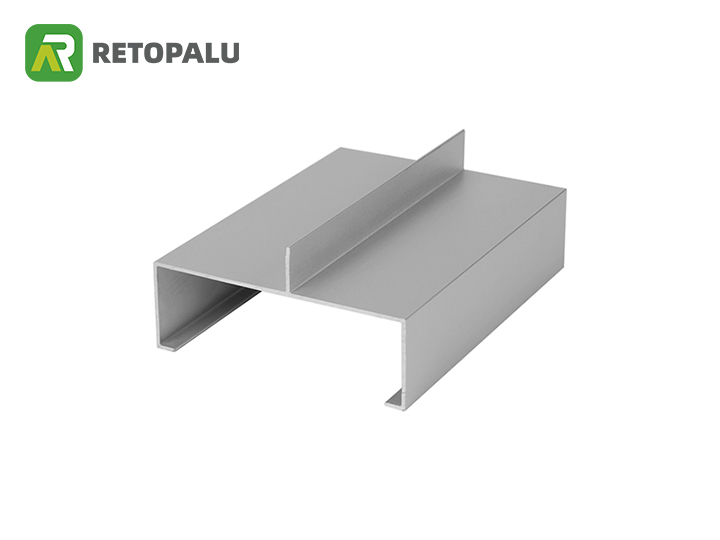

Solar panel aluminum extrusion typically include the following major components:

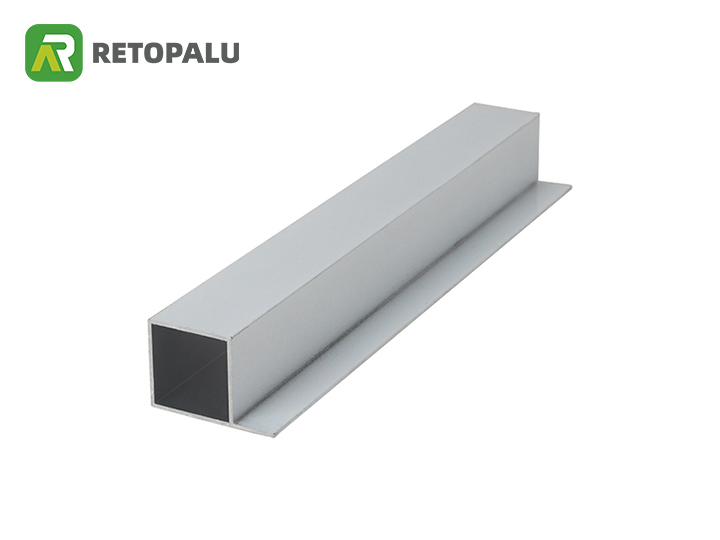

1. Bracket structure. The solar bracket aluminum profile is an important part of supporting the solar panel. It is mainly used to bear the weight of the solar panel and provide solid support.

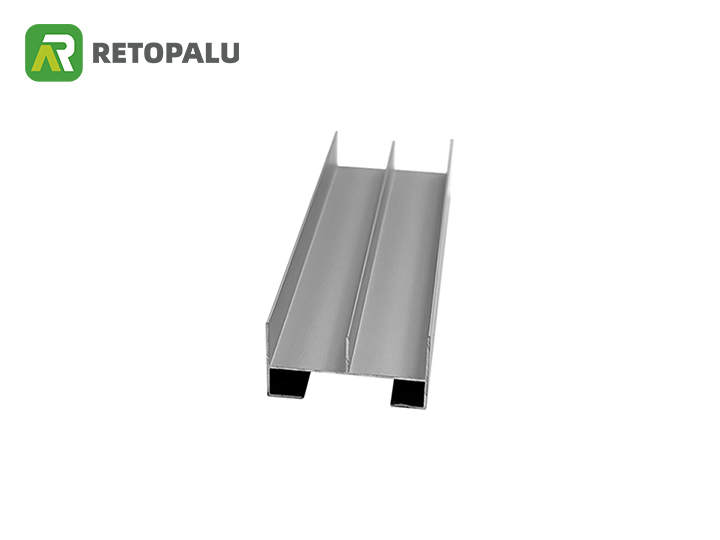

2. Connectors. Connectors are used to connect the various parts of the racking structure so that they can be assembled into a complete solar racking system. These connectors are also usually made of aluminum profiles, which provide good durability and stability.

3. Fixings. Aluminum solar profiles also include fixings. These fixings secure the solar panels to the racking structure and prevent them from moving or swaying

4. Accessories and fittings. Aluminum solar panel frames also have accessories such as anti-slip gaskets, gaskets, and security screws. These accessories are used to enhance the stability and safety of the solar racking system while protecting the solar panels from damage.

What aluminum alloys are used for aluminum solar panel frame?

The two most commonly used raw materials for solar panel aluminum extrusions are 6063 aluminum alloy and 6005 aluminum alloy. The main metal elements of these two alloys are aluminum, magnesium and silicon. Most of the common aluminum profiles for doors and windows are 6063 aluminum alloy. 6005 aluminum alloy is a bit harder. It is mainly used to support large size solar panels.

Alloying elements: the most important element in solar aluminum profiles is aluminum. Its content is usually above 90%. Other alloying elements are silicon, manganese, copper, and magnesium. Different aluminum alloy profiles may also contain trace elements such as zinc, iron, titanium, and chromium.

Trace elements such as iron, titanium, and chromium play the role of secondary alloying elements in solar aluminum profiles. These alloying elements can improve the strength, hardness, wear resistance and corrosion resistance of aluminum alloys.